SELECTIVE ABSORPTION FUSION

SAF™ technology powers a new plastic powder bed fusion process to achieve higher volume manufacturing of end-use production parts. This technology enables comprehensive control of the printing process to deliver accurate, consistent, and repeatable parts with engineering-grade thermoplastic materials.

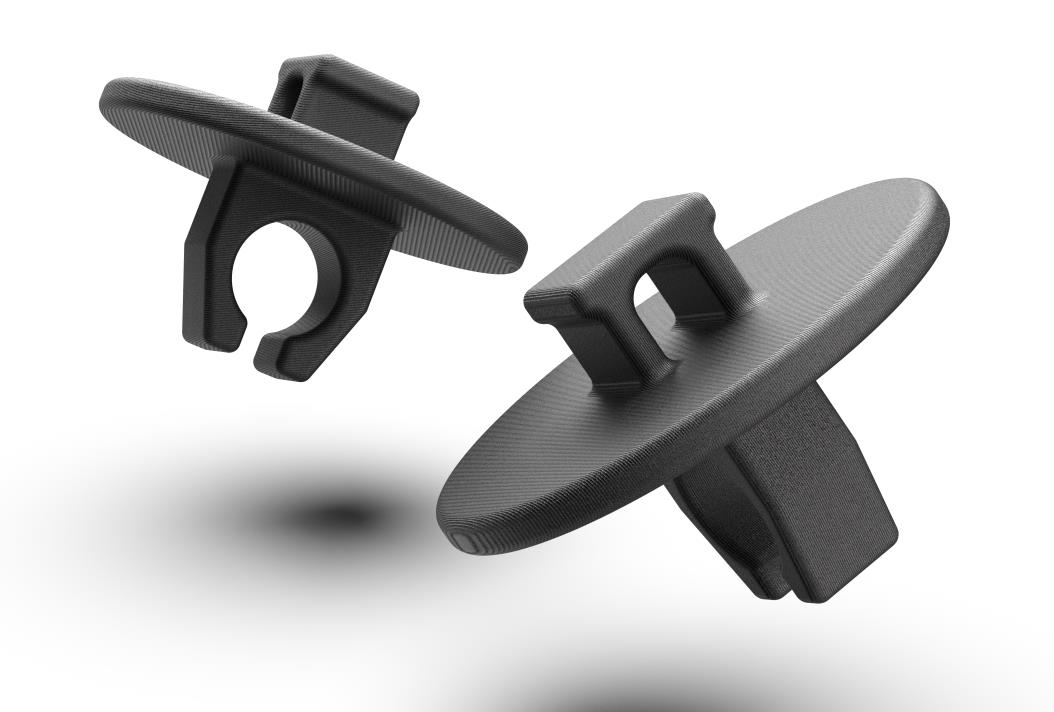

SAF™ technology produces small to medium functional plastic parts with tighter tolerances than SLS with an improved surface finish perfect for end-use components.

Built from the ground up with production-level printing in mind, SAF™ delivers exactly what you need – production quantities and competitive prices, all backed by the industry-leading production capabilities of Objective3D Direct Manufacturing.

FAQs ON SAF

What is the difference between Selective Absorption Fusion (SAF™) and Selective Laser Sintering?

SAF™ technology is also a powder bed fusion technology developed with industrial-grade technology for production manufacturing. It provides better aesthetics and mechanical performance than SLS.

What geometries are best suited for Selective Absorption Fusion (SAF™)?

SAF™ is ideal for components with complex geometries, including parts with internal cavities. Parts that are produced with SAF™ remain encased in powdered material, which is self-supporting, thereby eliminating the need for additional supportive structures on or within the components.

What Materials are available?

SAF™ will utilize Stratasys High Yield PA11 material with the elongation and impact strength of Nylon 11 but with better surface finish and feature definition and a formulation geared toward higher volume production.

What finishes are available for SAF™ Parts?

SAF™ parts are media blasted after breakout and have grey finish and can be dyed black afterwards. We recommend dyed black as the default finish for parts using SAF™.

SAF MATERIALS

High Yield PA 11

SAF™ currently offers Stratasys High Yield PA11 material for production. This rugged high-performance polymer is a 100% bio-based material derived from sustainably produced castor oil. Stratasys High Yield PA 11 is well suited for higher volume production, and it provides high ductility and impact strength along with excellent surface finish.

Consistent Production Grade Parts

This white paper provides the methods and results for assessing geometric accuracy of the H350™, using a Stratasys designed giveaway part. The part is representative of a potential end use of the H350 and is built many times across the bed. The H350 allows customers to qualify their production to produce consistent additively manufactured production-grade parts using SAF™ technology. With SAF™, customers can control part qualities build-to-build in a way that optimizes part performance, consistency and ultimately production yield, leading to less waste and a lower cost per part.

And if you’re ready to build now, use our no-hassle Quote Tool.