LASER SINTERING MATERIALS

Long use cycles and part fatigue have met their match. Depend on our standard Nylon 11 and Nylon 12 materials and variety of reinforced nylons with property-enhancing fillers for light-weight, highly durable and heat and chemical resistant parts.

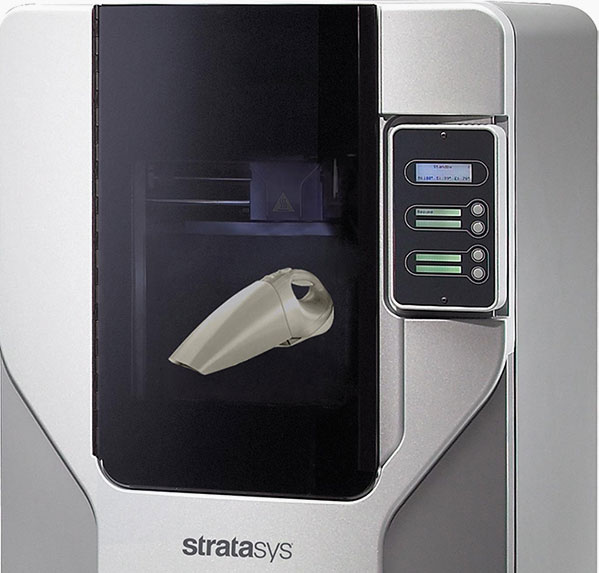

SLS PROTOTYPE

(0.004”-0.006” Z; 0.030”-0.050” X/Y)