MANUFACTURING TOOLING AND AIDS

Businesses can’t afford to let production lag or quality control slip. On the shop floor, you rely on specialized jigs, fixtures, templates, gauges, and other aids to maintain precision and efficiency. The advanced manufacturing services we offer are ideal for rapidly creating the complex and custom manufacturing tools. Whether these key parts are used for forming, location, cutting, assembly, testing, or inspecting, we have the expertise—and the ITAR plus ISO 9001 certified capabilities — to build the tools and aids you need to exceed your production expectations.

BENEFITS AND APPLICATION

Covers, Surrogate Parts, and Plugs

To keep your manufacturing line moving smoothly, we can deliver fast turnaround of plugs, FOD covers, and blanks using technologies such as SL, FDM, and CNC Machining. Our expertise extends to masks for painting complicated geometries, which can help achieve easy finishing and protection.

Form Tools, Cooling Fixtures, and Patterns

Low cost setting boards, form tools, sand casting patterns, and cooling fixtures can be manufactured in just 2-4 days using 3D printing and quick-turn CNC Machining.

Locating Templates and Drill/Saw Guides

Enterprise 3D printing technologies allow you to create customized templates and guides with even the most complex twists and turns. And with additive manufacturing technologies like SL and FDM, you can make conformal integrated designs a reality.

Inspection and Test Fixtures – Calibration and Shim Fixtures

Test fixtures built with durable LS, FDM, or CNC Machining materials consistently identify whether newly manufactured products have the correct design, placement, and accurate measurements. Affordable, custom fixtures fitted to your design and tolerance requirements can help decrease costly inspection time using conventional methods.

Holders and Assembly Line Fixtures

Pick and place fixtures, transportation and storage fixtures, and even fixtures used for static-sensitive transistors are possible through 3D printing. Protect your part and ensure accurate assembly.

Tooling

3D printing and Urethane Casting provide cost effective alternative tooling options for thermoforming, molding, and casting operations. Soft tooling with Urethane Casting relies on 3D printed master patterns to lower costs for low volume production. Fused Deposition Modeling (FDM) with high performance thermoplastics is a reliable tool for thermoforming production, able to withstand pressures, and repeated use.

TECHNOLOGIES USED FOR MANUFACTURING TOOLING AND AIDS:

- PolyJet

- Fused Deposition Modeling (FDM)

- Investment Casting Patterns

- Stereolithography (SL)

- CNC Machining

MANUFACTURING TOOLING AND AIDS IMAGE GALLERY

3D PRINTED VACUUM FORMING TOOL GRANTS CURT G. JOA CUSTOMIZATION AND A COMPETITIVE EDGE

Thanks to customized vacuum forming tools built using Fused Deposition Modeling (FDM), Curt G. Joa was able to decrease lead time, decrease warehouse cots, and minimize assembly time.

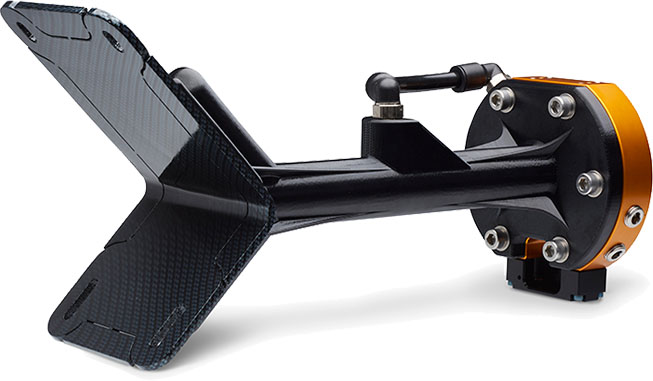

When to 3D Print Carbon Fiber Layup Molds

Fiber-reinforced plastics are a unique solution for engineers in aerospace, automotive and sporting goods because of their incredible strength-to-weight ratio. Learn how you can use FDM and PolyJet to make fast carbon fiber layup molds.

Ready to start building your concept model? Getting a no-commitment quote is easy and fast when you use our Quote Tool.