Tooling + Injection Moulding

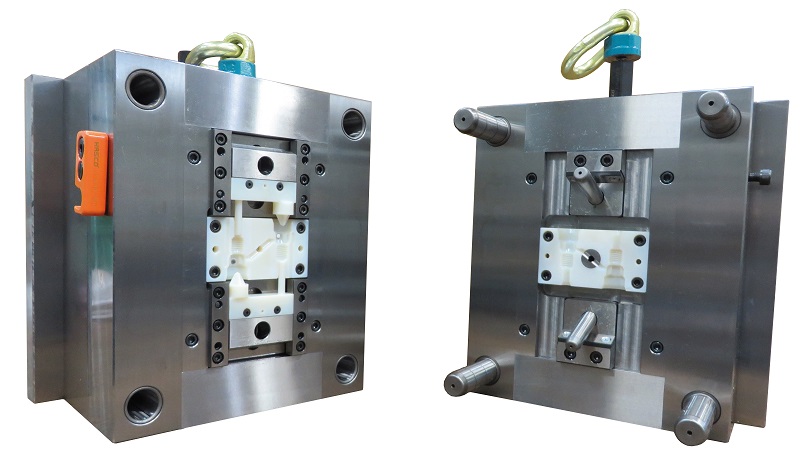

Prototypes are most useful when they’re made of the same plastic as the final production part. And during product development, quick feedback is essential. But it’s hard to justify the cost to create injection moulded prototypes when they require the same expensive, time-consuming tooling as production parts — even though you only need a small quantity of parts for testing.

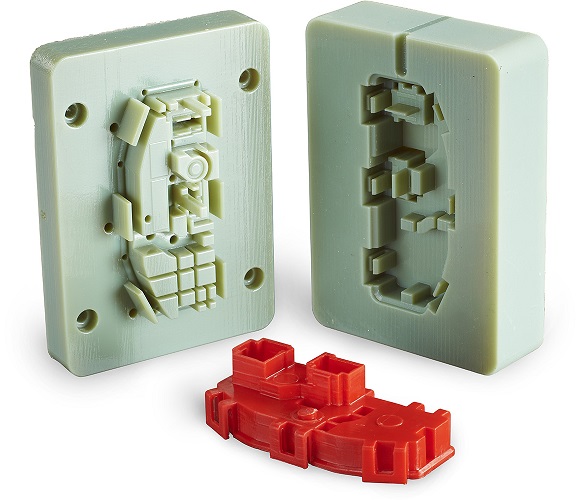

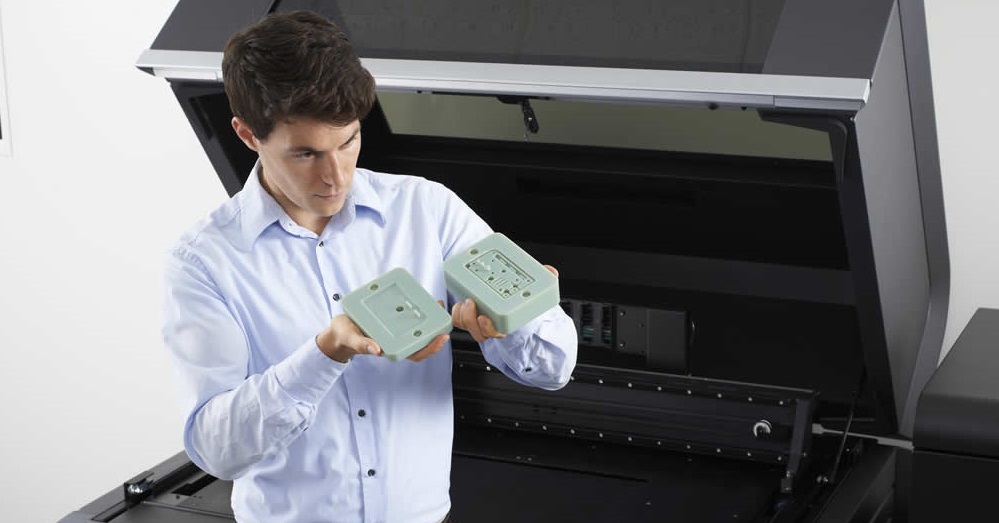

3D printing your prototype moulds with PolyJet technology offers a fast, affordable way to produce injection moulded prototypes. Designers and engineers can test their work more frequently and more accurately, and go to production with confidence. Product managers can shrink time to market and products can turn out better.

BENEFITS of Tooling and Injection Moulding

PolyJet technology creates smooth, detailed, accurate moulds. Digital ABS 3D printing material is strong enough to hold up to short injection moulding runs of about 10 to 100 parts. You can install the 3D printed mould directly onto your injection moulding machine. If testing reveals that you need to make a design improvement, you can alter the mould in directly in CAD and 3D print the next iteration. Depending on size, the new mould can be printed and ready to inject in a day.

PolyJet 3D printed moulds are not production tools. But during the design and testing phase, they offer a clear advantage over conventional injection moulding. Product designers and manufacturers can use these moulds to perform thorough functional testing without worrying about cost-prohibitive tooling. Flaws based on the final production process, geometry or choice of plastic can be discovered early, when they are easiest to fix. This can reduce costly, time-consuming mould corrections, increase product innovation and speed product development.

Injection Molding Materials

As you consider your options for low-volume injection molding, talk to our experts.

We can work with any production plastic material your project requires, but the most common options are listed on our site.

Injection Moulding Design Guidelines

For detailed engineering specifications and considerations, including the advantages and disadvantages of using injection moulding for a variety of applications, read the Injection Moulding Design Guidelines.

And if you’re ready to build now, use our no-hassle Quote Tool.

REQUEST YOUR QUOTE