SELECTIVE LASER SINTERING

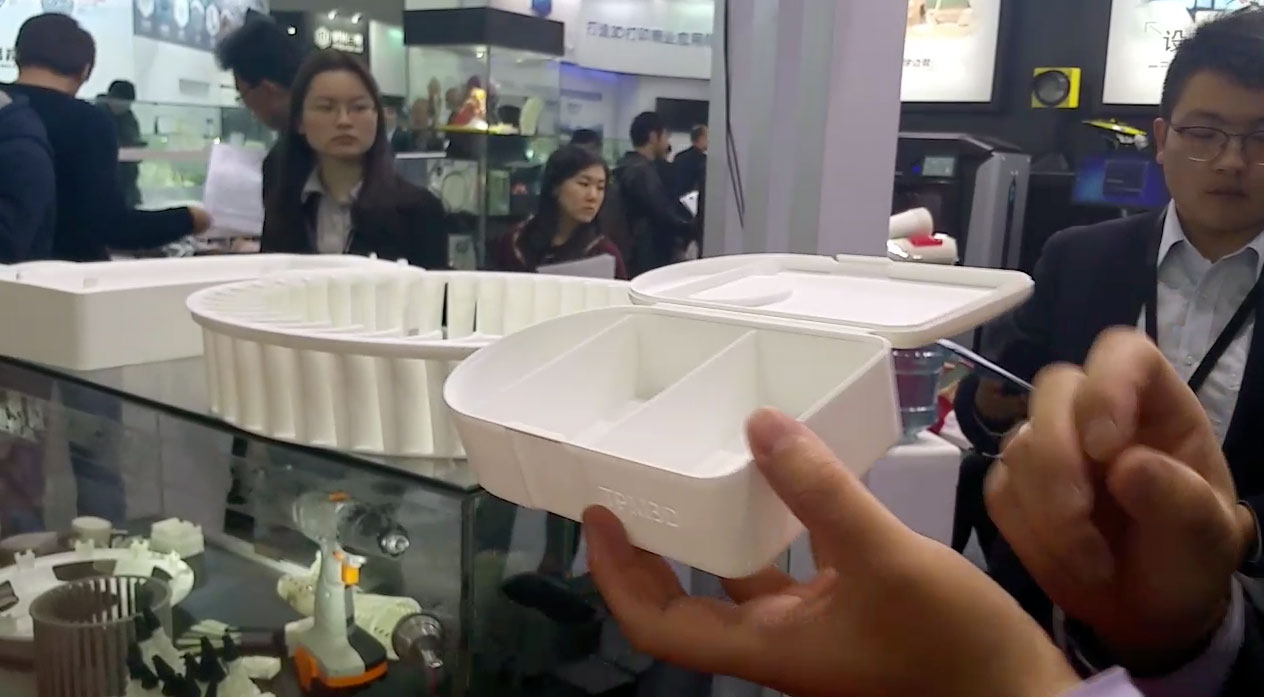

Selective Laser Sintering (also known as LS or SLS®) builds complex parts directly from 3D CAD data via a heat laser that fuses or sinters powdered thermoplastics. Similar to other 3D printing technologies, it enables part consolidation and complex geometries, however LS is unique in that it eliminates the need for support structures. Parts built with LS are printed in a bed of self-supporting powder; the excess powder is easily shaken out during post-processing. It is an affordable way to build durable production parts in low volumes. Common applications include ductwork, control surfaces, brackets, clips, clamps, fuel tanks and flight-certified parts.

BENEFITS OF Laser Sintering

FAST DELIVERY

Laser Sintering can provide sturdy, functional prototypes as little as 24 hours. Multi-component designs can be incorporated into single structures, allowing engineers to produce complex features and geometries in one print, and eliminating the need for assembly. Additionally, reduced secondary processing means quicker delivery to you.

Variable Characteristics

Prototypes from Laser Sintering are functional and stable in a variety of taxing environments. The nylon 11 and nylon 12 materials used in Laser Sintering can be reinforced with property-enhancing fillers, such as carbon fiber or glass, to produce strong parts that meet a variety of performance requirements like high tensile strength, flexural strength, impact resistance, and heat deflection temperatures. LS prototypes created with these materials are perfect for applications that experience variable temperature exposure, like fuel tanks and electronic enclosures.

Little to No Finishing Needs

One key advantage to Laser Sintering is that each part is encased in powder as it is made. The surrounding powder reinforces the parts and eliminates the need for support structures that require removal after production. With ready-to-use prototypes off the printer, little to no finishing needs reduces costs and delivery time.

LASER SINTERING MATERIALS

LS offers a variety of materials and reinforced formulations for lightweight and highly durable parts that can be heat and chemical resistant.

An Insider’s Guide to Laser Sinterting

Mastering successful Laser Sintering parts at any 3D Printing Experience Level.

DOWNLOAD THE WHITE PAPER

And if you’re ready to build now, use our no-hassle Quote Tool.