Fused Deposition Modeling

Fused Deposition Modeling (FDM) works with production-grade thermoplastics to build strong, durable and dimensionally stable parts with the best accuracy and repeatability of any 3D printing machine technology

BENEFITS OF FDM

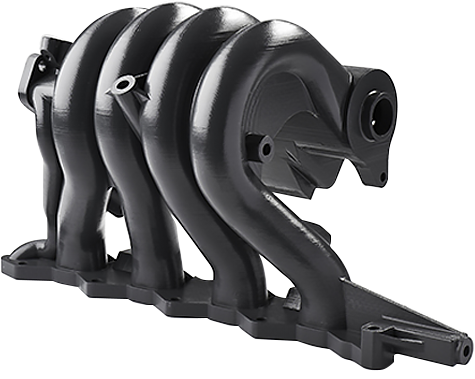

Design Freedom

Complex geometries and cavities that would otherwise be problematic become practical with FDM technology.

Exceptional Materials

Supported production-grade thermoplastics are mechanically and environmentally stable.

Ease of use

The technology is clean, simple-to-use and office-friendly.

FDM Materials

Build parts in the same strong, stable plastics you’re familiar using in injection molding.

FDM allows you to use real engineering-grade thermoplastics that are ready for harsh environments,

tough testing, and demanding applications.

3D Printing with FDM

Download a guide to the FDM process and its applications in manufacturing.

DOWNLOAD THE WHITE PAPER

And if you’re ready to build now, use our no-hassle Quote Tool.