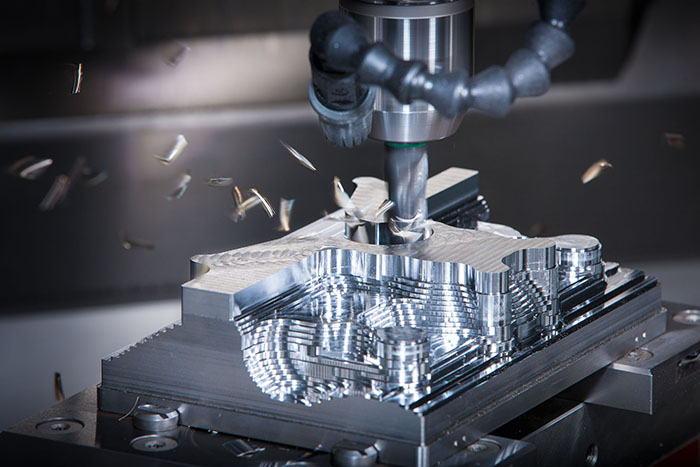

CNC Machining

CNC machining at Objective3D Direct Manufacturing represents an optimal solution for projects demanding high precision and specialty materials. Excelling in producing prototypes, large-scale production models, master patterns, and intricate jigs and fixtures, it offers unparalleled accuracy and material diversity. This method stands out in the manufacturing sector for its reliability and quality, making it an indispensable choice for those seeking the best in conventional manufacturing techniques.

BENEFITS of CNC Machining Services

Capacity

Objective3D Direct Manufacturing is your ideal partner when you’re looking to complete your CNC project quickly. Powered by a wide variety of CNC equipment such as single axis lathes which is ideal for executing round parts such as nozzles, engine components, and threaded shafts – as well as cutting edge 5-axis machines, which substantially reduce turnaround time by eliminating intermediate setups and enabling undercuts and off-axis features.

Speed

Powered by an online quoting system, Objective3D Direct Manufacturing provides the fastest quotes in the industry for machined parts. Your projects are started the same day the order is received.

Finishing Options

With an experienced team of workshop technicians, we offer a variety of finishing options to improve the mechanical and aesthetic properties of your CNC machine part(s), including painting, anodizing, EMI and RFI shielding, and hand polishing.

CNC Machining Materials

We can machine virtually any engineering material, including plastics, metals, alloys, and foam or tooling board.

Pick from our vast inventory, or speak with your Project Engineer to special order custom materials.