Fused Deposition Modeling MATERIALS

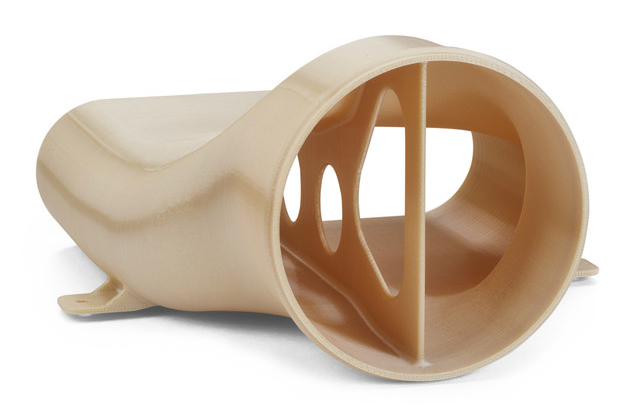

FDM Technology works with production-grade thermoplastics to build tough, durable parts that are accurate, repeatable and stable over time. 3D print your concept models, prototypes, tools and production parts in familiar materials like ABS, PC and high-performance ULTEM 1010 and ULTEM 9085.